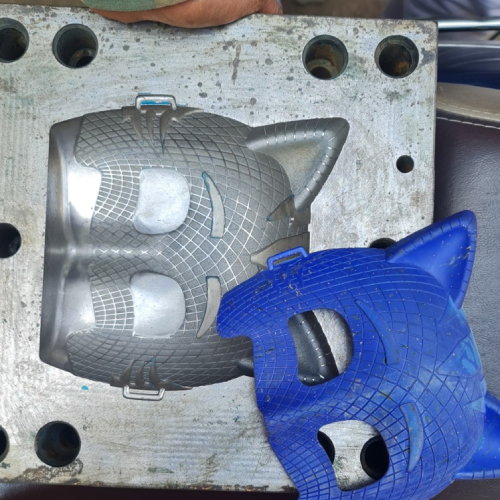

Two major factors that have made us one of the leaders in the domain of Etching services are earnestness to service and customization as per requirements. Today, we at SHARDA ETCHING PROCESS are counted among the leading service providers, helping clients with their needs of all Metal Mold Etching, 3D-Laser Etching, On Site Etching services, Grit Blasting, Shot Blasting, Sand Blasting, Glass Bead Blasting, mold Diamond Polish, Chrome Plating, Blow moulds, Plastic moulds, Casting moulds, Roll etching, 3d roll etching, House hold products and Injection moulding products etc. These services are offered to varied clients, based globally. We provide these services for products such as Footwear industry, Plastic molded Furniture industry, Embossing Cylinders/Rolls, Electronics industry, Automotive industry, House-hold Plastic-wares, Aerospace industry etc.

View More

Precision etching excellence, enhancing products with intricate detail, cutting-edge technology, and unwavering commitment to quality.

Leading the industry with innovative etching solutions, setting new standards in precision, and inspiring manufacturing excellence.

Elevate manufacturing through precise etching, empower clients with quality solutions, and inspire creativity for exceptional products.

Designing and casting metal require lot of expertise and precision. Therefore, we have a team of diligent professionals, who have vast knowledge in this domain. They provide immediate and quality services as per client specifications. Also, they use computer generated customized designs to provide best results. Besides, they provide Bead Blasting, Glass Bead Blasting services at nominal rates, which save time and transportation. These services provided are duly assessed by our experts for their quality standards.

Now we are happy to introduce a hassle free transfer service for our valued clients, which ensures:

What We Do

On-Site Laser Etching

On-Site Laser Etching

Sharda Etching Process specializes in on-site laser etching services. Our cutting-edge mobile equipment and experienced technicians bring precision laser etching directly to your location.

Read More Transport Services

Transport Services

Sharda Transport offers reliable and efficient transport services. With our diverse fleet and experienced drivers, we provide transportation solutions tailored to your cargo and logistics requirements.

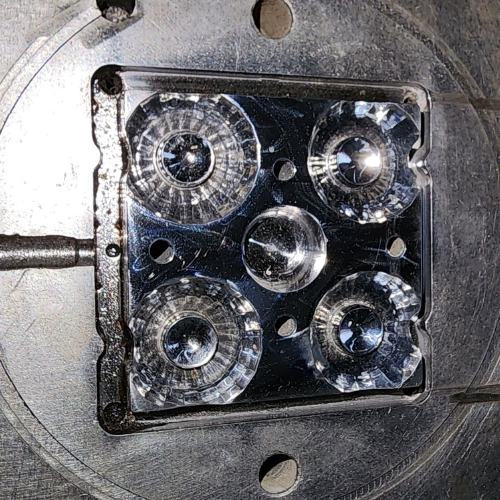

Read More Diamond Polishing

Diamond Polishing

Sharda Etching Process offers exquisite Diamond Polishing services. Our skilled craftsmen and advanced equipment provide impeccable precision and brilliance to your diamond products.

Read More Sand Blasting

Sand Blasting

Sharda Etching Process offers professional Sand Blasting services. Our experienced team and specialized equipment provide efficient and effective surface preparation and finishing solutions for diverse industrial applications.

Read More On-Site Services

On-Site Services

Sharda Etching Process offers convenient on-site services for various industrial needs. Our experienced team brings our expertise and equipment to your location, ensuring efficient and effective solutions tailored to your requirements.

Read More Bead Blasting

Bead Blasting

Sharda Etching Process offers professional Bead Blasting services. Our experienced team and specialized equipment provide efficient and effective surface finishing solutions for diverse industrial applications.

Read More Chemical Etching

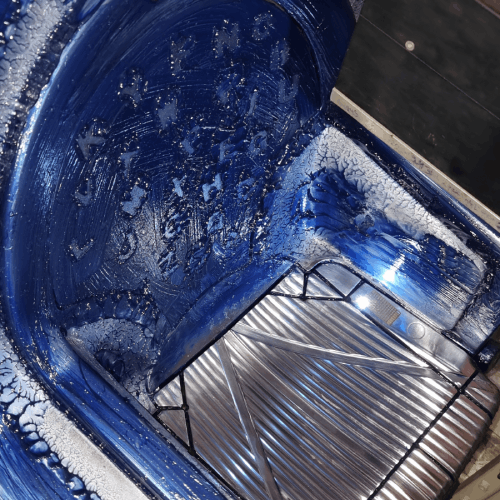

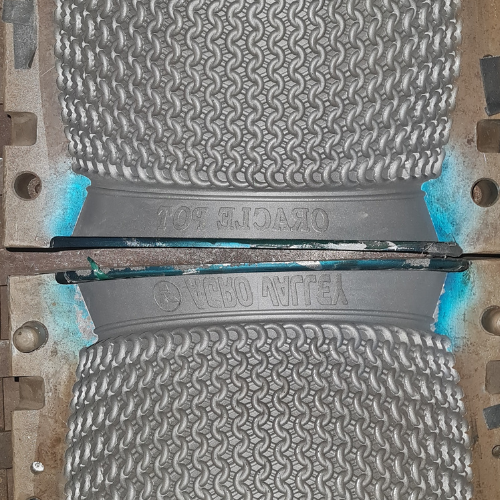

Chemical Etching

Sharda Etching Process offers advanced Chemical Etching services. Our cutting-edge technology and expertise deliver precise and intricate etching solutions for a wide range of materials and industries.

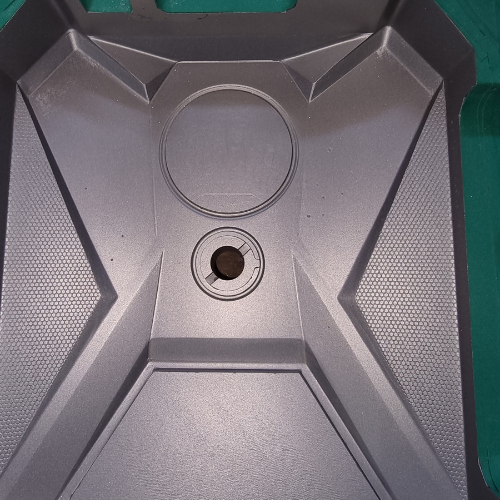

Read More 3D/2D Engraving

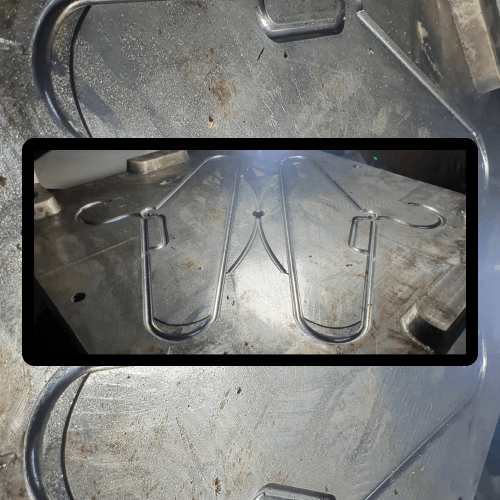

3D/2D Engraving

Sharda Etching Process offers precision 3D/2D Engraving services. Our advanced technology and skilled craftsmen create intricate and detailed engravings on various materials for diverse industrial applications.

Read More Grit Blasting

Grit Blasting

Sharda Etching Process offers professional Grit Blasting services. Our experienced team and advanced equipment provide efficient and effective surface preparation for a wide range of industrial applications.

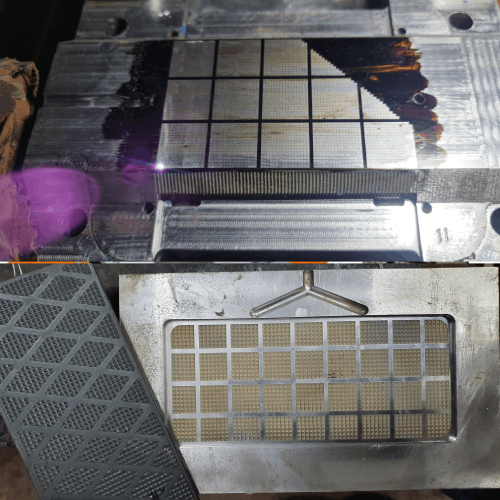

Read More Roll Etching

Roll Etching

Sharda Etching Process offers precision Roll Etching services. Our advanced technology and expertise ensure the highest quality and precision in etching rolls for various industrial applications.

Read More Hard Chrome

Hard Chrome

Sharda Etching Process offers exceptional Hard Chrome Plating services. With our advanced technology and expertise, we provide durable and corrosion-resistant chrome plating solutions for various industries.

Read More Shot Blasting

Shot Blasting

Sharda Etching Process offers top-tier Shot Blasting services. Our advanced equipment and skilled team ensure efficient and effective surface preparation for a wide range of industrial applications.

Read More Laser Blasting

Laser Blasting

Sharda Etching Process offers top-notch Laser Blasting services. Our state-of-the-art laser technology ensures precise and efficient surface treatment, perfect for a wide range of industrial applications.

Read More Laser Etching

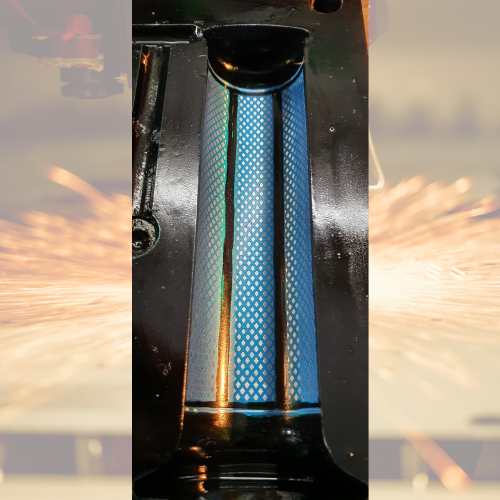

Laser Etching

Sharda Etching Process offers advanced Laser Etching services. With our state-of-the-art technology and expertise, we deliver intricate and precise etching solutions for a wide range of materials and applications.

Read More

At Sharda Etching, we take pride in being a leader in the etching industry, offering a wide range of etching services with a commitment to unmatched precision, exceptional quality, and expert guidance for all your etching needs. There are several reasons why you should choose us for your etching projects:

Choosing Sharda Etching means choosing a trusted partner that delivers excellence in etching solutions. From concept to completion, we are dedicated to transforming your ideas into reality with precision and quality that exceeds expectations. Experience the Sharda Etching advantage today!

News and Events

Chemical etching is a fascinating and versatile process that unlocks the potential for creating intricate designs and patterns on various metal surfaces. From industrial applications to artistic endeavors, this technique has revolutionized the way we manipulate and adorn metals. In this blog post, we delve into the world of chemical etching techniques, uncovering the methods, materials, and creative possibilities they offer.

Read Details

Chemical etching, a sophisticated and precise metal processing technique, has become a cornerstone in various industrial sectors. By selectively removing material from metal surfaces, chemical etching offers unparalleled precision and flexibility, making it a go-to solution for crafting intricate metal components. In this article, we delve into the wide-ranging industrial applications of chemical etching, uncovering its impact on industries such as aerospace, electronics, automotive, and beyond.

Read Details

Chemical etching, a precise and versatile process for creating intricate designs on metal surfaces, has a rich history of applications in various industries. As technology continues to advance, the future of chemical etching holds exciting prospects, ranging from innovative techniques to sustainable practices. In this article, we will explore some of the key trends and advancements shaping the future of chemical etching.

Read Details